Shadowden wrote:When do you think you will be welding the subframe in? Would like to see that. You going to mig, tig, or stick it?

Most likely MIG. I'm no expert welder (hardly even an average one). My plan is to just get some sold beads on it and then drill a hole through the frame and the subframe and put a long bolt and nut through it. This will be a backup in case the welds fail. But you're welcome to come watch haha.

Today was a good day. I have to give a MASSIVE thanks for Eric and Matt because today wouldn't have been possible without Eric's muscle and Matt's engine hoist. Eric drove all the way up from the Springs to help me pull the engine and transmission out of the REPU. I had the engine pretty stripped with the exhaust, intake mani/carb, radiator, etc all removed. Only thing we had to do was drain oil, remove bellhousing bolts and motor mount bolts, and lift her out. And surprisingly, it went really smoothly. One bellhousing bolt was a little rounded but luckily I was able to get my Visegrips on it and it came right out.

We also pulled the 3spd auto gearbox with the engine hoist but chaining it to the hoist and lifting it out. Again, not too bad save for a stubborn blown trans mount bushing. And we managed to catch most of the trans fluid in the drain pan! Amazing!

And, I WAS going to save this info until it actually happened, but due to the mishaps today, might as well let the cat outta the bag. I bought a 13B-REW enigne off eBay! It's a complete swap with engine, harness, ECU, trans, etc. I actually bought it about 2 weeks ago. And today was the day I had scheduled with UPS freight for it to be delivered, which is why Eric was coming up.

So right on time, UPS comes with the engine. SWEET. It's on a pallet and wrapped in black shrink wrap so I can't easily see anything about it. As the UPS guy is lowering it off the liftgate Eric notices it looks like a TurboII trans mount on the back. Weird. So the pallet is dropped off and I cut the shrink wrap off. That's a T2 tranny...and it's a T2 engine. WTF!! I check the packing slip and it's has all the right info on it.

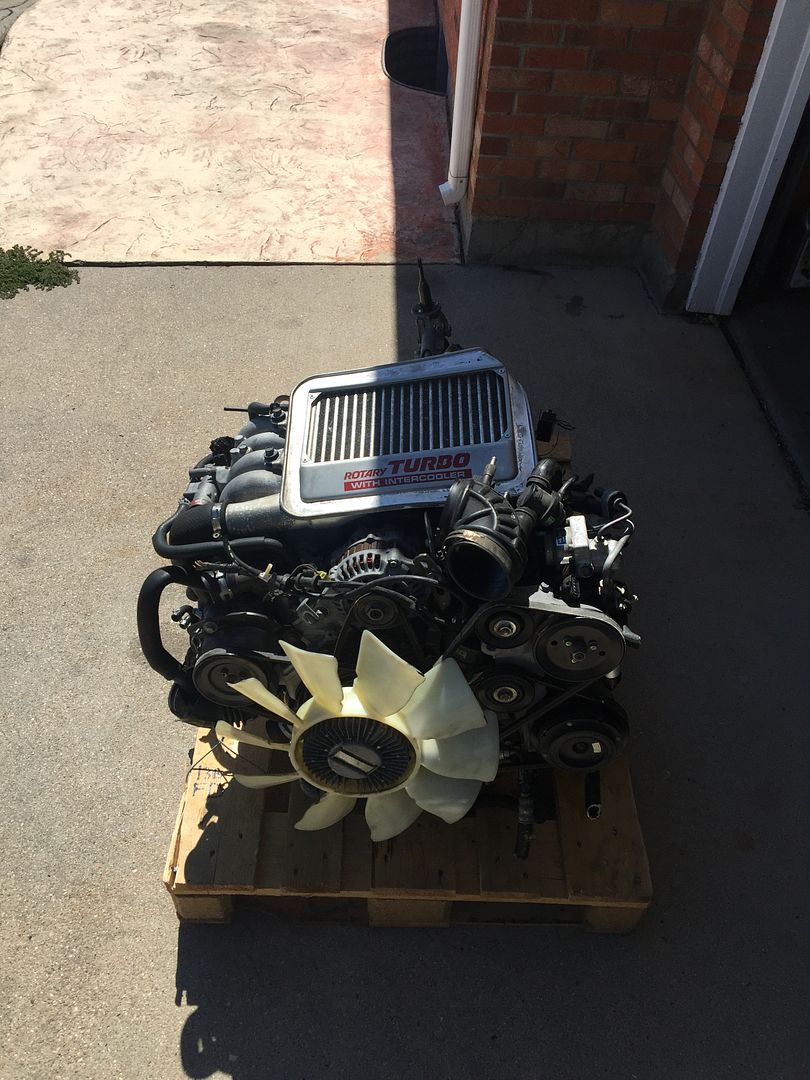

So this is what I ordered:

.jpg)

.jpg)

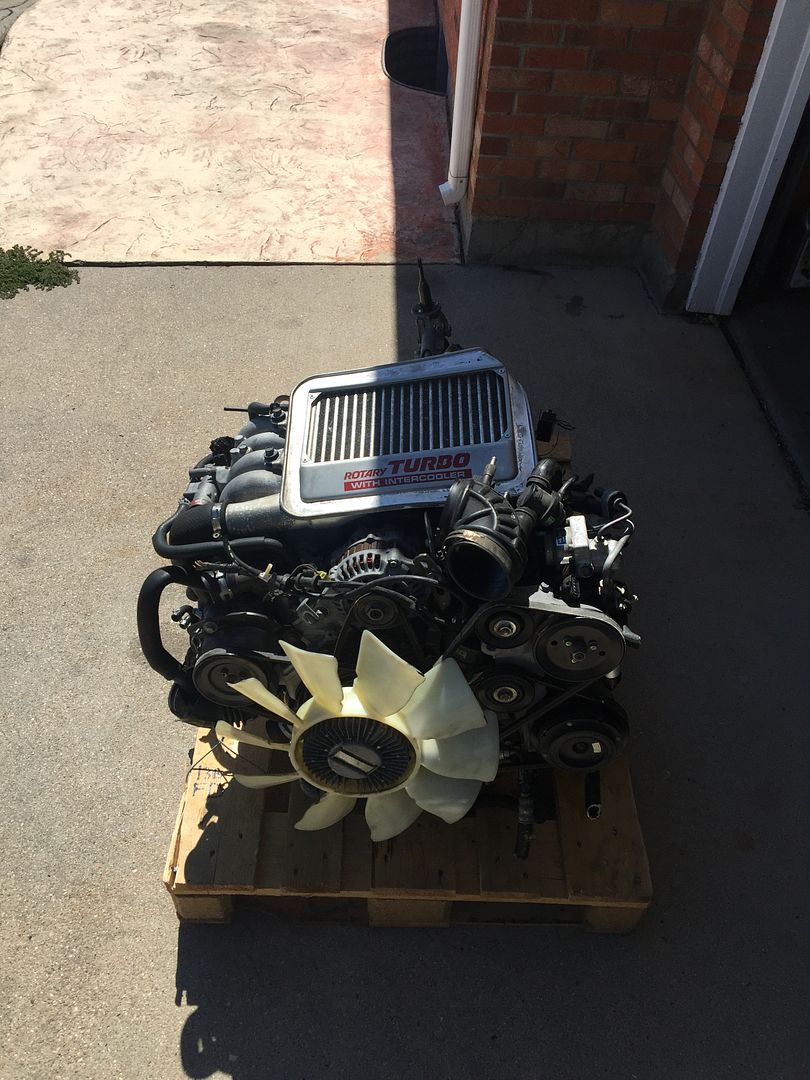

I got THIS:

Clearly a T2 engine/trans and not what I ordered.

I call up the number for the engine import company fully expecting no one to answer or to get a machine and leave a message. Surprisingly, someone answers and I tell them what's going on, he takes all my info and says he'll call me in an hour or so. 30 minutes later I get a call, he asks me to email him pictures of the freight label and engine. I do and he calls me right back and says they sold the engine I bought and the one I received the same day and his shipping guy got them switched somehow (great). Luckily the engine I ordered is yet to be delivered and still sitting in a warehouse, so they are rerouting it and having UPS freight come pickup the wrong engine tomorrow.

I don't have the right engine yet with all the pieces, but so far they have handled this pretty good, even though it's 100% their mistake. I always say everyone makes mistakes, it's how we correct them.

While this was all going on, Eric got his rotary compression tester and we ran a comp test on the T2 engine just to see what it's got. It's showing 81psi front rotor and 0 (as in ZERO) psi rear rotor. We were having a hard time believing the tester so I hook up an old analog piston comp tester to the rear rotor and sure enough, during cranking, the needle never moves. The rear rotor is completely toast!

So, it will be another week until I have the right engine, which I'm hoping to maybe find the time to weld the subframe in so once I get this new engine I can work on dropping it in. I will for sure compression test it as this T2 engine now has me worried.

So there's the updates. Plan is to have the RIGHT engine by next week and hopefully that one has compression and I can drop it right in once I get that subframe welded in.

Again, BIG THANKS to Eric and Matt!

that truck is that heavy ? My FD wights 2950 with me in it this is with the lighter 8.8 diff setup and no PPF. The FB race car weights 2480 with me in it. Figure it would be way lighter that's crazy.

that truck is that heavy ? My FD wights 2950 with me in it this is with the lighter 8.8 diff setup and no PPF. The FB race car weights 2480 with me in it. Figure it would be way lighter that's crazy.

.jpg)

.jpg)