I ordered cable terminal ends to fit all the different bolt sizes. Selection at local places was pretty slim. I finally got them the other night and made the cables and installed them. I should also take this time to say the very next day after drilling the hole in the passenger side I realized that the cable would be right next to the exhaust. DERP. So I drilled another hole in the driver's side, this time using a hole saw again, and it came out PERFECT. And these cables are a lot larger than the old ones so the carpet sticks out a bit more now, I hope I can get the knee oval back on.

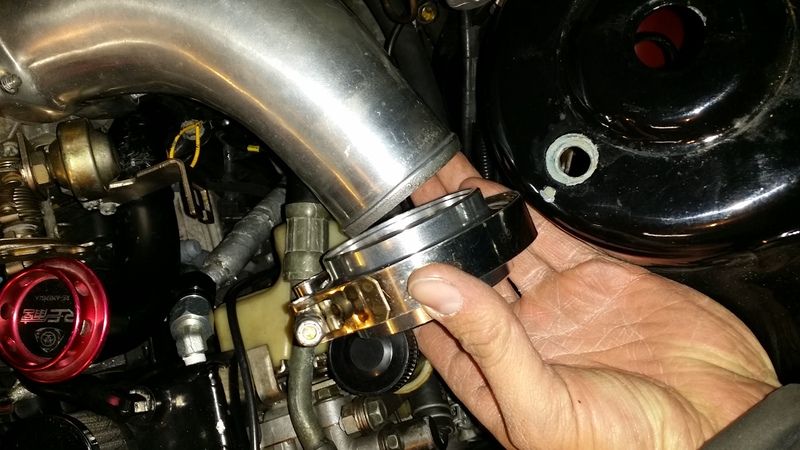

So the top of the Turbosmart wastegate actuator takes a 3AN coupler. When I finally got the coupler I turned it into the top of the actuator and I couldn't get it in all the way because it started pushing the valve down, so I cut off the end of the fitting and then wrapped teflon tape around the end, along with installing an o-ring to help seal it.

I haven't done anything with the knuckles yet, and I've only pressed out a few bushings on the suspension arms. I'm dreading doing that for fear of breaking something haha, but it's going to end up holding up the project if I don't get to it soon. I did buy some Project Kics R40 lug nuts, they are open end so I can use them with the extended studs. I'm hoping to get those soon.

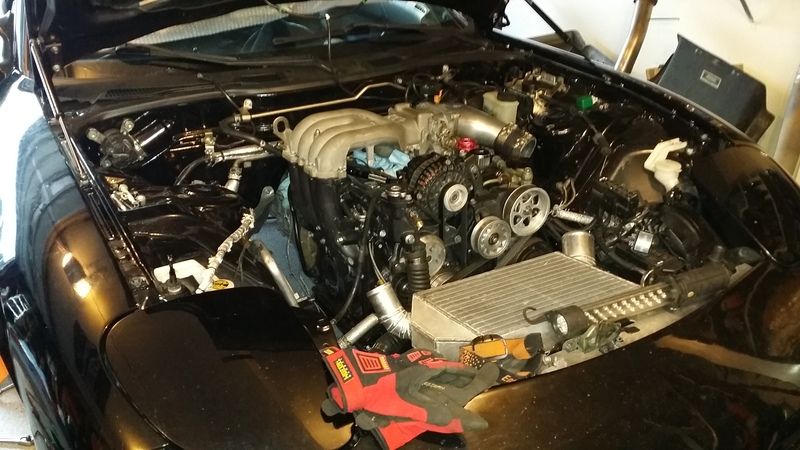

I got the turbo back from Andy and the oil line Whisler made me fits pretty well, so no worries there. Not yet anyway lol, assuming it doesn't leak.

I ended up being very disappointed in the Timken bearing press kit. I discovered I can't use it for much. I might try to take it back.

I got the Amsoil filter and test fit it. I think it will work, and I'm going to rearrange some things to hopefully make it fit even better. I didn't get a restriction indicator, just the filter and pre-filter. And when I was putting the pre-filter on I dropped the filter against the mock engine and damaged some of the netting on the outside, really pissed me off haha. But there shouldn't be an issue in functionality and the pre-filter hides it pretty well, and I plan on putting that part towards the ground anyway.

I'm going to use some thick aluminum I have to make the brackets to drop the condenser.

I got the map pocket and after I installed it I discovered that the Bubble Tech lid was the old version that was more purple compared to the stock black plastics, so I swapped out the lid anyway. Then the lid detached from the pocket because the set screw came out of the lid and shifted out too far and the lid was shifting back and forth anyway. And I broke part of the new pocket haha, but at least it wasn't anything important. So the next time I assembled it I used nylon washers on each side of the lid so it doesn't shift now, it's nice and snug. I also got the card/coin holder from Japan. I really like it but it was also a ridiculous purchase lol. And one of the times I had the door panel off I fixed the mirror switch tabs. One of the sides wasn't holding so the right side of the switch would sit out from the panel, now it's nice and snug too. And I'm talking to a guy from 7club that has speaker covers for the rear speakers, but one of them has a broken piece missing. I'm not sure if it will be noticeable though when they're installed and they're the cheapest option.

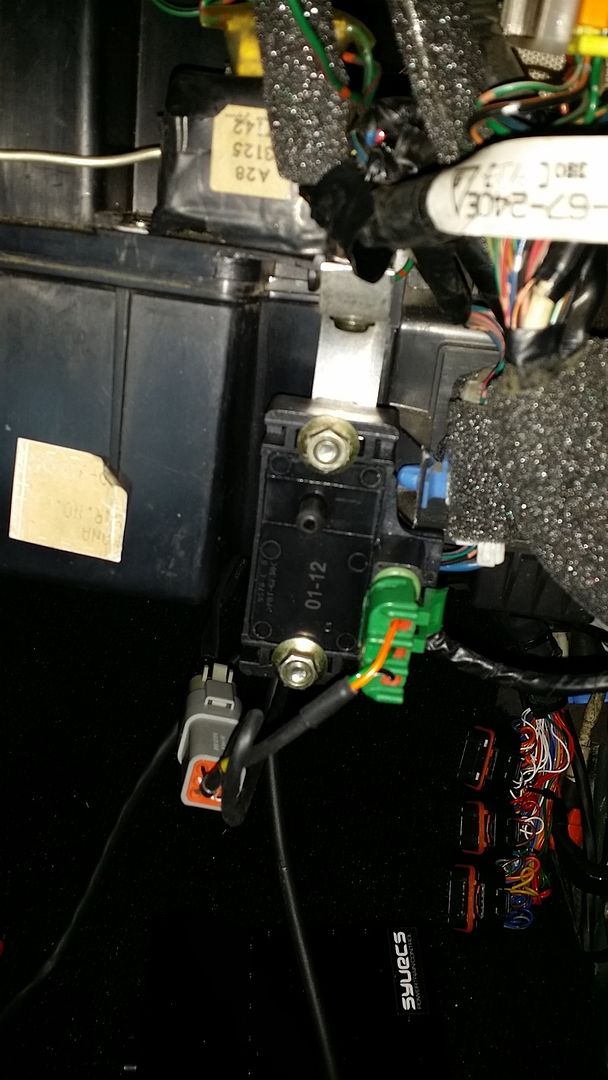

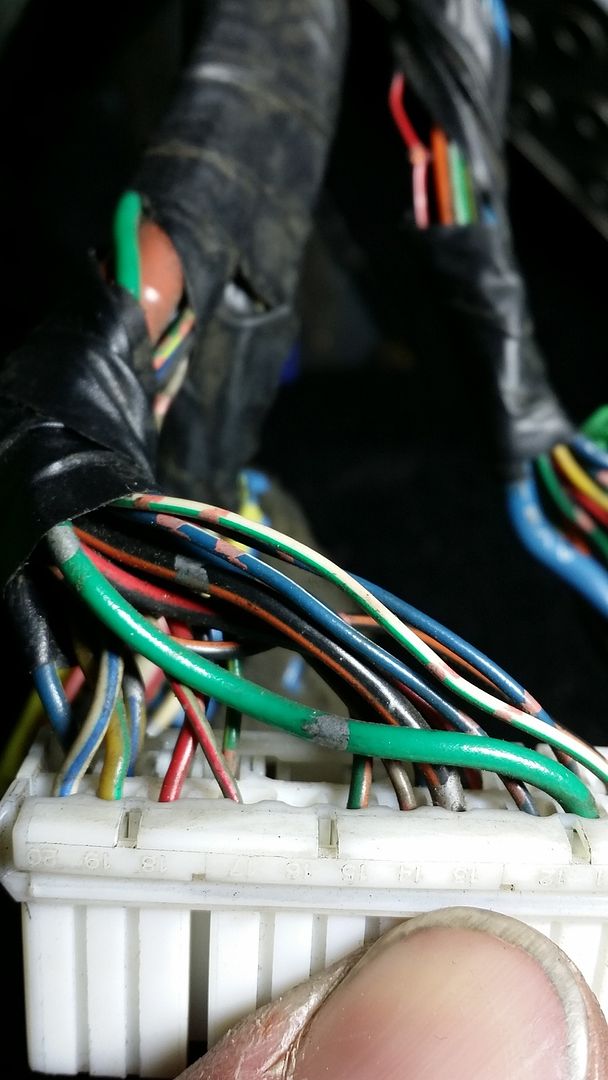

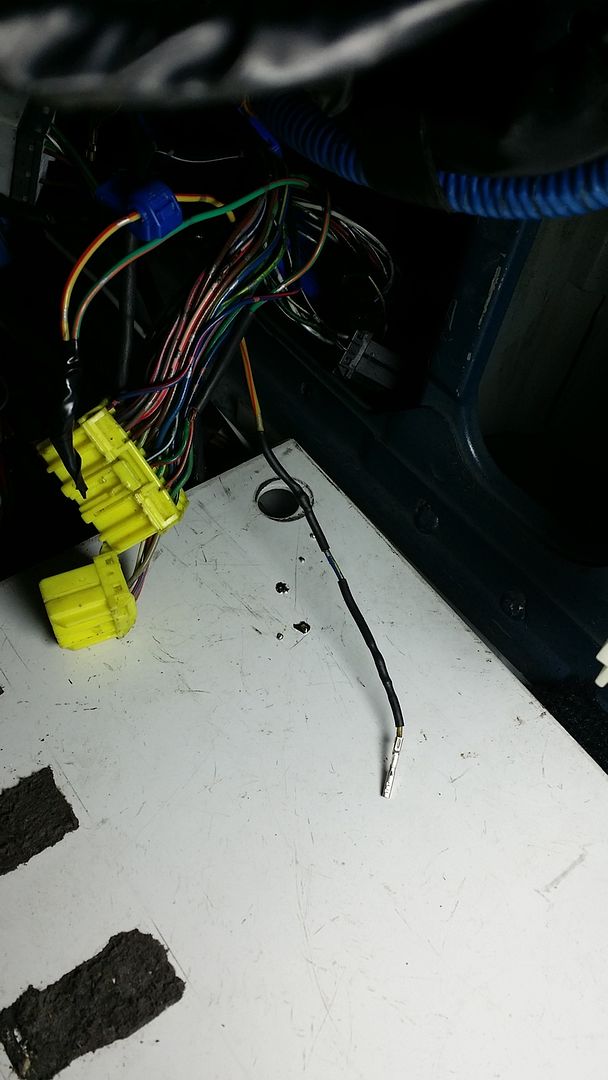

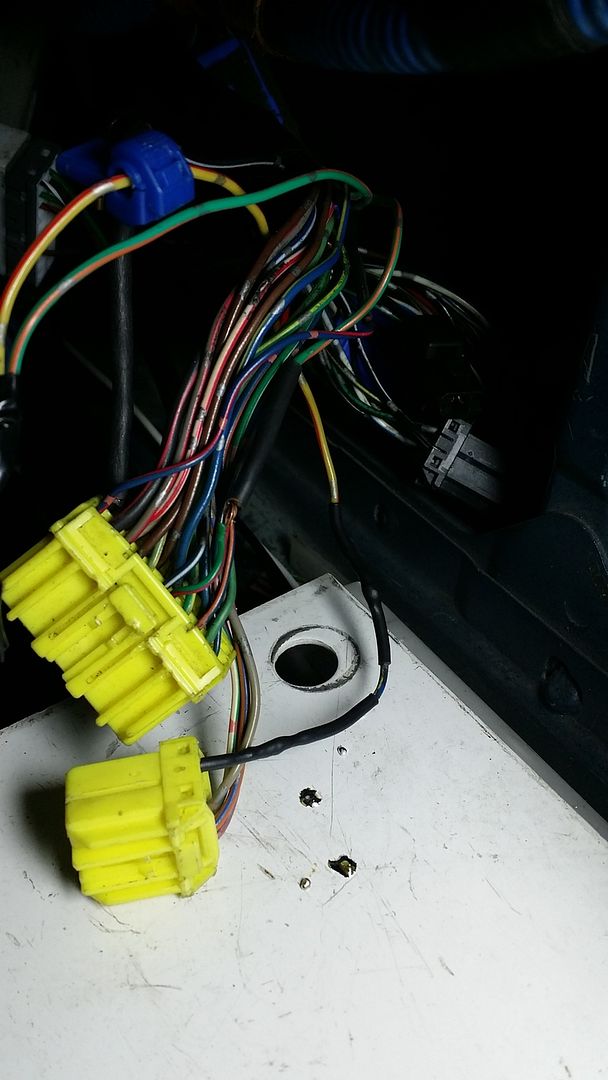

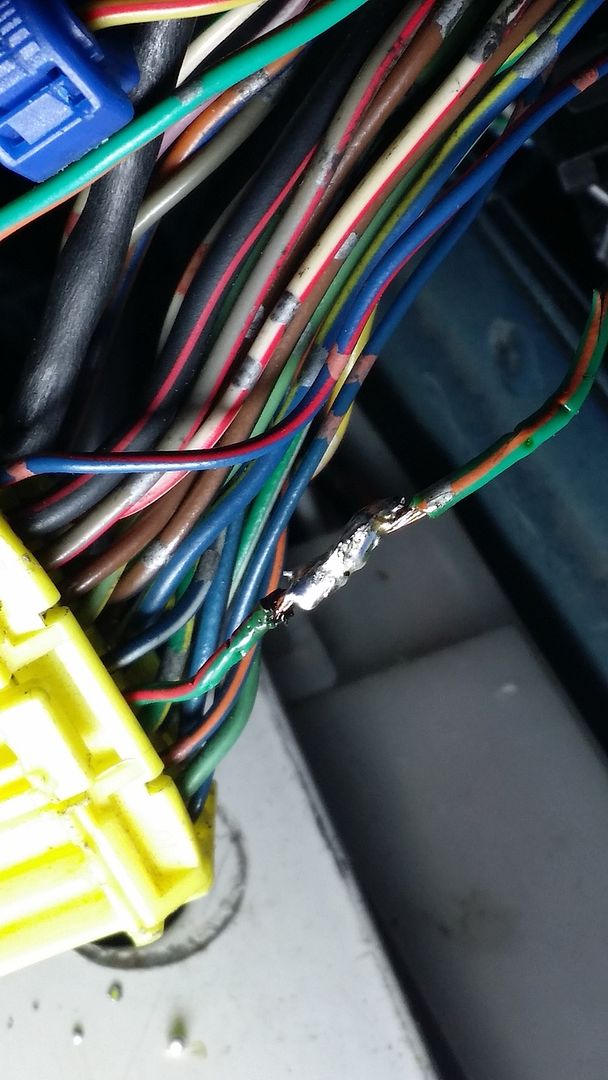

I figured out the water injection wiring tonight. I only hooked up one of the wires for a couple reasons. For starters, it's the only one I plan on using because it's for RPM, and also because it splices into the chassis harness and the other wire (for TPS, which I won't be using) taps into the new harness that Chris made and I didn't want to take a chance on ruining that. And while I was looking at the wiring by the ECU I noticed a couple wires on the chassis harness that were about to break, so I fixed those yesterday. The first one I did I added an extra length of wire, but I should have just reconnected the two pieces after cutting off the old heat shrink, like I did with the second one. Oh well. I'm really just happy to be finished with it.

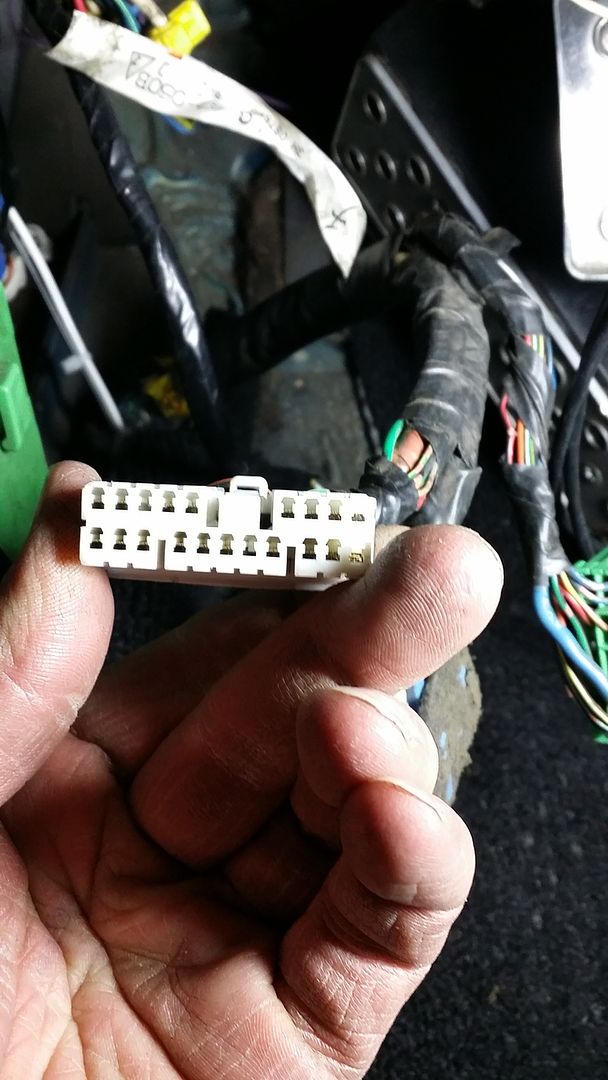

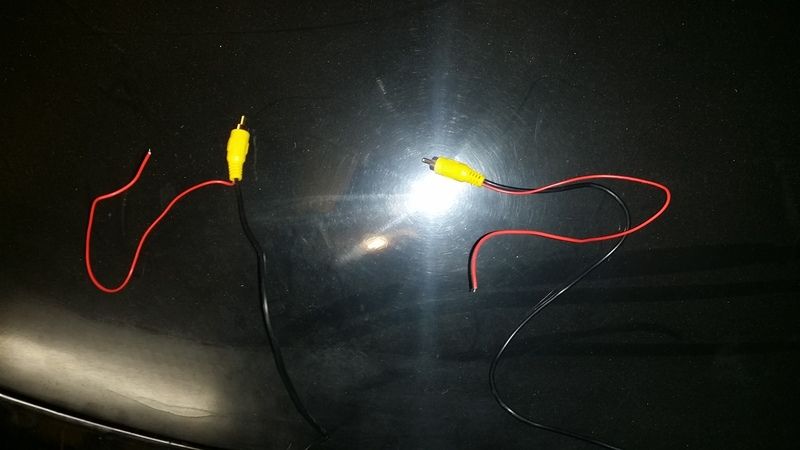

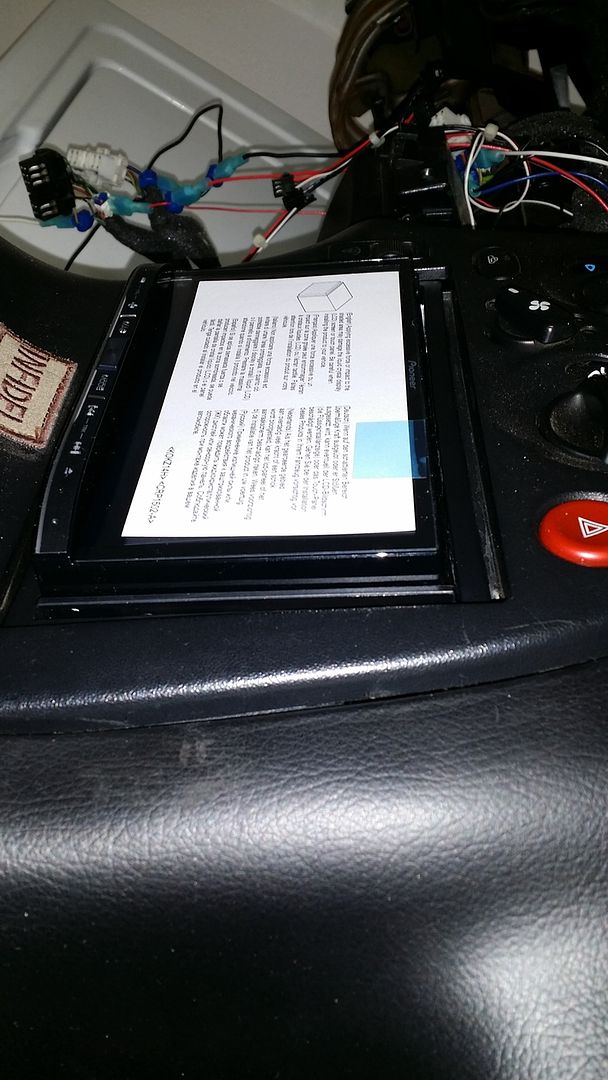

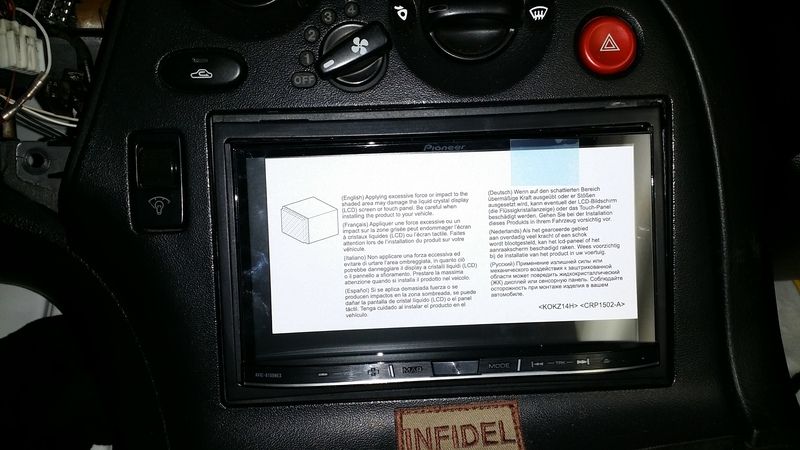

I got some Kenwood 5-way 6x9 speakers from Best Buy and then discovered they were too large. The stock speakers are 5x7 but you can also install 6x8 and I was thinking it was 6x9. So I took them back and got some Pioneer 5x7/6x8 speakers and installed those, then wired them up the other night after running some 18ga wire from the dash area to the speakers. I thought I got pics of the rear speakers installed but I guess not. But while I'm on the subject of audio, I picked up another stereo. This is Pioneer's flagship model, currently anyway. The AVIC 8100NEX. It has Apple Car Play and Android Auto so I'm pretty sure it should connect to the app on my iPad mini once I figure out how to make the iPad compatible with Apple Car Play. It also has a backup camera, built in navigation, DVD playback...I'm probably forgetting a lot. I really like it though. I might get a screen protector for it too.

I'll cover the rest of the updates in the next post.