lOOkatme wrote:I am going out on a limb here, pulsing voltage to the pumps, and the pumps fluctuate due to the voltage differences?

I know, its a stretch, but is the voltage steady to the pumps?

It's a possibility, but I would imagine it would have been steady when he had it wired directly from the battery. Maybe not though.

I emailed CJ Motorsports and Charles told me that using Teflon line can contribute to pulsations because it's more rigid and not as forgiving as rubber. Also, larger injectors that open and close abruptly. Chris said Wednesday he'll have all the parts to bypass the check valves, and he's also going to make lines to go from the hardlines to each fuel rail, basically making it one pump feeding each rail. I'm not crazy about that idea because with them Y'd together, even if one pump fails they both still get fuel, whereas one rail would starve if a pump failed with them ran the way he's going to do it. However, as of right now he's just doing it to test it out, and if it works I'm not going to change it back, I'll keep it that way. There are failsafes to protect the engine anyway in the case of a pump failure. I'll probably get a different secondary rail if I keep it that way though, since the current one has the branch off to feed the primary rail. And if the separate lines work, I won't need the check valves anymore anyway, I don't think. If I do need them, I'll move them to the engine bay right off the hardlines probably.

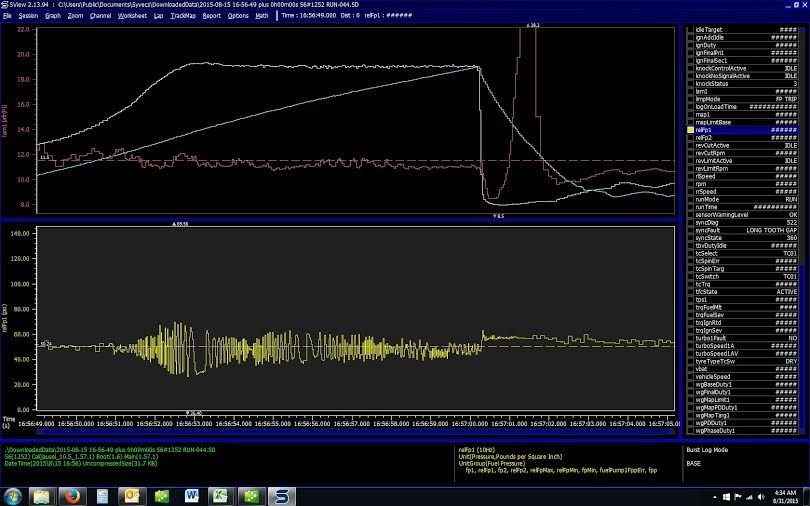

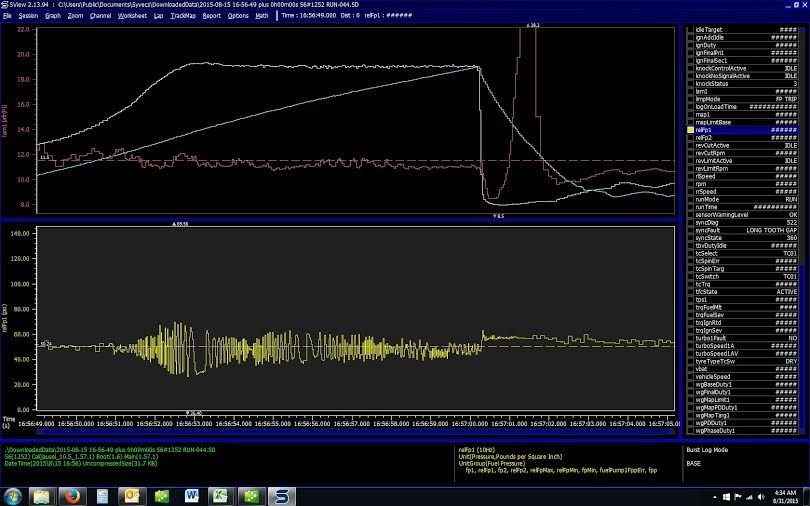

Here is a log from a 20psi pull on the dyno.

Here is some of what Chris said about it...

I think it’s a real problem and not just data. I didn’t have an issue on the dyno where I thought, “Hey! This isn’t right.” But, in hindsight, there were some oddities in having to add fuel in a couple areas where I didn’t think I should. There are also some somewhat lengthy dips in the pulses that I can’t simply chalk up to injector pulsation.

To answer your questions from before, the big pulsations don’t show up until 5 or 6 psi of boost. The largest drops in pressure are right around 30 psi. The highest peaks are about 20 psi high. I’ve attached a log of a 20 psi pull on the dyno that illustrates everything very well. I’ve also attached a screenshot of the log. As far as the issue getting worse. I probably misspoke there. It’s true that I hadn’t had the ECU trip a low pressure fault until this week but the logs this weekend versus what we did on the dyno aren’t really any different. It just happened that I got a longer stretch of low pressure than I had at any time on the dyno. The ECU trip has a time element to it. Pressure has to be low for a given amount of time before the ECU trips. So it’s not so much that the pressure pulses we much greater but that we got a longer dip than anything we’d seen to that point. In the end, the ECU did its job and shut everything down.

Here are some other things he's said in the past week or so, but keep in mind these are old so some of the things he's already tried and didn't work.

Did some more testing and I'm now pretty confident there is a real fuel pressure issue and not just a sensor anomaly. The issue gets worse when the secondary injectors come on line but is also present with just the primaries. Basically, as injector duty goes up, the issue vets worse. I can also see the issue on the gauge in the dash. So it's not localized to the rear of the car.

I didn't relocate the pressure reference for the FPR but I did make a restrictor and put it in the vac line. It's common to do this with MAP sensors to smooth out resonant pulses. That did nothing. Also ran it with the fuel fill cap removed to make sure the tank was vented and that did nothing.

My guess, and it's just that, is that there is a fuel feed issue to the pumps. It really acts like the tank isn't vented properly. Similar to pouring gas out of a jug and getting the "glug-glug" when it's not vented well enough. My thought is, if it were a voltage issue or one pump was laying down, you'd simply have low pressure, not pulsating pressure. When volume demand is low, there is no issue. When volume demand goes up, you get the pulsations.

I may have time before you arrive to pull the pumps out and check the pickup socks. But, other than that, I really wasn't planning on allocating diagnostic time. This is something I'm sure you could sort yourself. Thoughts?

Other than that, it's ready to go. I put some 93 in it and the fuel blend is reading about 60% ethanol. The flex trims are working properly and maintaining correct mixtures. I'm going to add some more 93 and check again to make sure it's consistent at closer to 10% ethanol.

Took the pump assembly apart to get that bad wire out and like I guesses, the Delphi connector sets for the pumps aren’t doing well. The seals are already falling apart. I’d recommend removing the connectors, doing butt splices, and covering those with PTFE heat shrink. Sounds like a plan?

The pulsations aren't present at low load. You need to make about 6 psi of boost to see the pulsations. At idle and low load the variance is only about 3 psi. At full load we're seeing up to 30 psi drops in pressure.

I'm going to make up some lines to run one pump to each rail and give it a try. I understand your concern but two things help in the event of a failed pump. One, the ECU is going to shut the engine down if pressure drops in the rail. We've already tested that. Two, the good pump can still back feed through the FPR to keep you running as long as the check valves are working correctly.

Only other idea I would have then is ID of the rails being too small. I doubt they're 5/16 because that would be REALLY small. Rails are usually 1/2", sometimes 5/8". With the big injectors, you'll want the rail ID as big as possible. The pulsation damper wouldn't hurt but I'm not sure it would solve the huge pulses we have. Give CJ a call and see what they say. My experience with them is that they make some really nice parts but haven't necessarily tested every combination of what they sell. Do you know anyone running 6 injectors plumbed the same way you have them? And if someone is running them, do they have access to good data? Remember, the car feels fine when you drive it.

He also did some more digging about the fuel hose in the tank and it turns out it may be OK with ethanol after all.