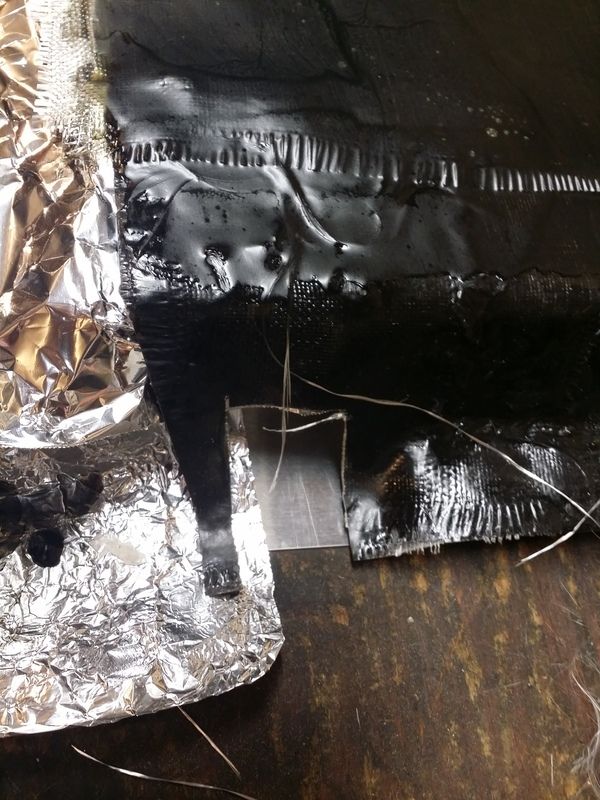

With this first piece, it's to direct air through the condenser and radiator by not letting it escape out the gap in the back, or out the sides. If it wasn't for the condenser this piece could have been mounted lower and it would work just fine. Unfortunately I believe the IC will be resting on this duct, so it will block the rear two inches of the IC unless I cut this piece as wide as the IC is or cut the back part off that wide and make another piece to direct the air up through those two inches of IC. If by some miracle it doesn't touch I'll be alright and not have to cut this piece at all. I'm praying for that lol.

I should be getting the AC line tomorrow. But I STILL have to order the refrigerant lol.

I did some troubleshooting on the water injection system today, and got NOWHERE. Basically, for some reason water is not being injected. The lights aren't lighting up on the control box anymore, and they used to at all times, even during idle. The box is getting power, the pump turns on, for some reason it's just not telling the injector to open I guess. I hooked up the laptop and it looked OK. So far I read in the instructions to use the same power that the ECU gets, and that's something I think I changed, but I don't remember for sure. I don't see why that would make that much of a difference though. I also changed to circuit breakers from fuses, but I don't see how that would make a difference either. I didn't hook up the TPS wire, just the RPM wire, but that's the only one I'm using. Maybe that's the problem though. I'm going to look into it more tomorrow. Unfortunately the kit I'm using was sold to Holley a few months after FJO released it, which was back in 2008/2009, and Holley no longer uses the control boxes, they use their ECUs to control the system. I'll email FJO if I have to and pray that they can troubleshoot the control box if I can't figure out anything else. In the mean time I'm going to start looking into other systems to see if there is something else that I can swap in without having to change too much.

I did some test fitting with the OMP HTE-R 400 today, and the super low seat rails I got from Adam Griffith that bolt the seat directly to the floor. Adam said he'd modify the rails for me to work with these seats. The seat has to be to the right a bit, against the tranny tunnel, otherwise the door is still somewhat difficult to close against the shoulder bolster. The rail kept the seat from leaning down too much, so it's leaned back quite a bit. The upside is it gives even more headroom with a helmet, I don't have to take the bottom cushion out. But I'd still rather not have it lean back that far.

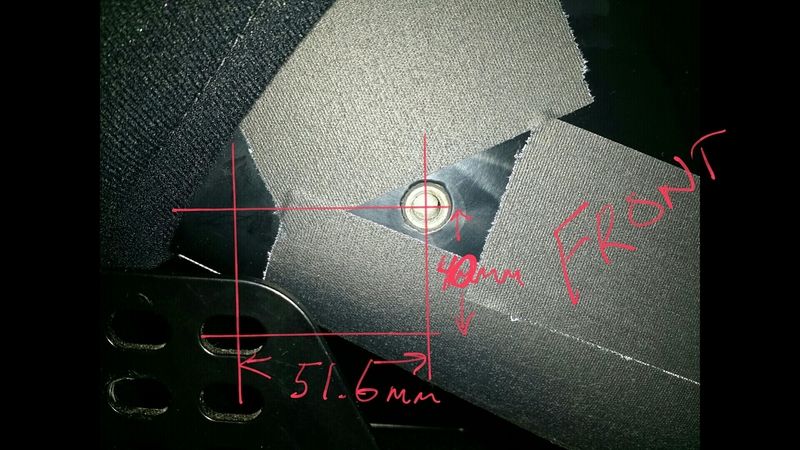

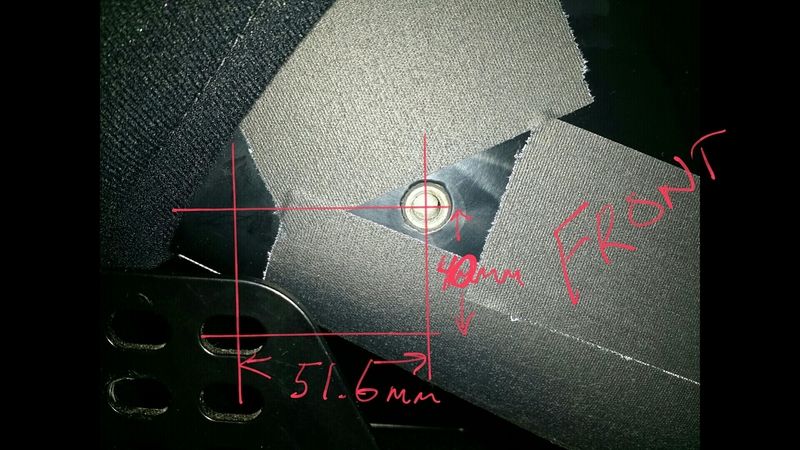

Obviously I had to take this pic outside the car because the ass was back too far to see with it inside the car, and I only took this pic so I could draw on it lol.