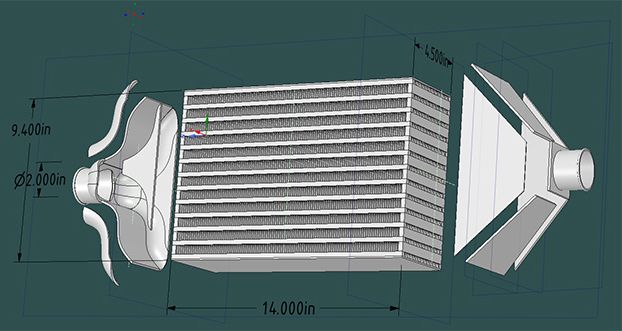

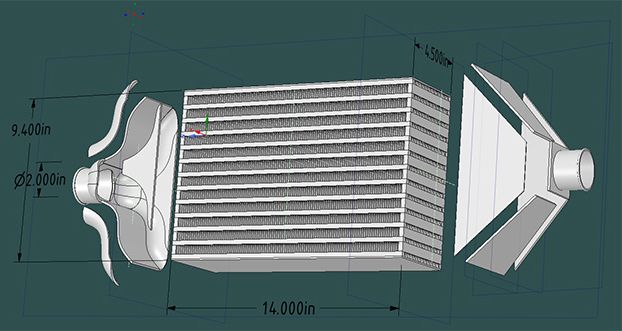

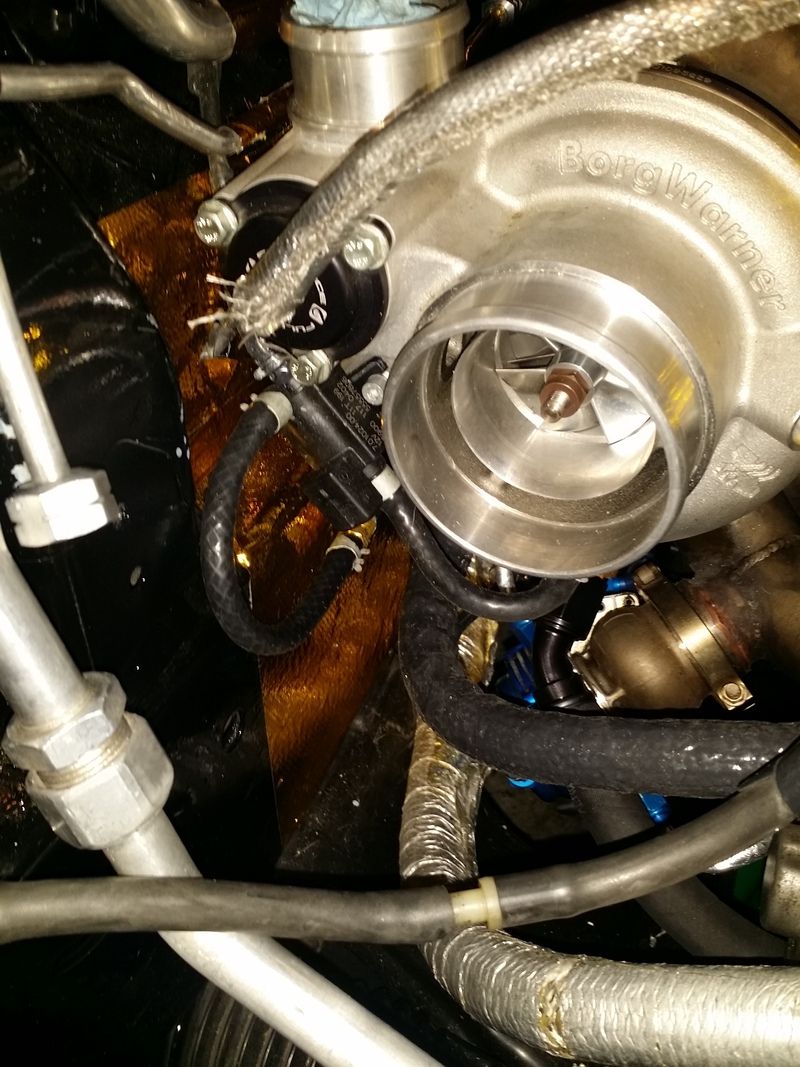

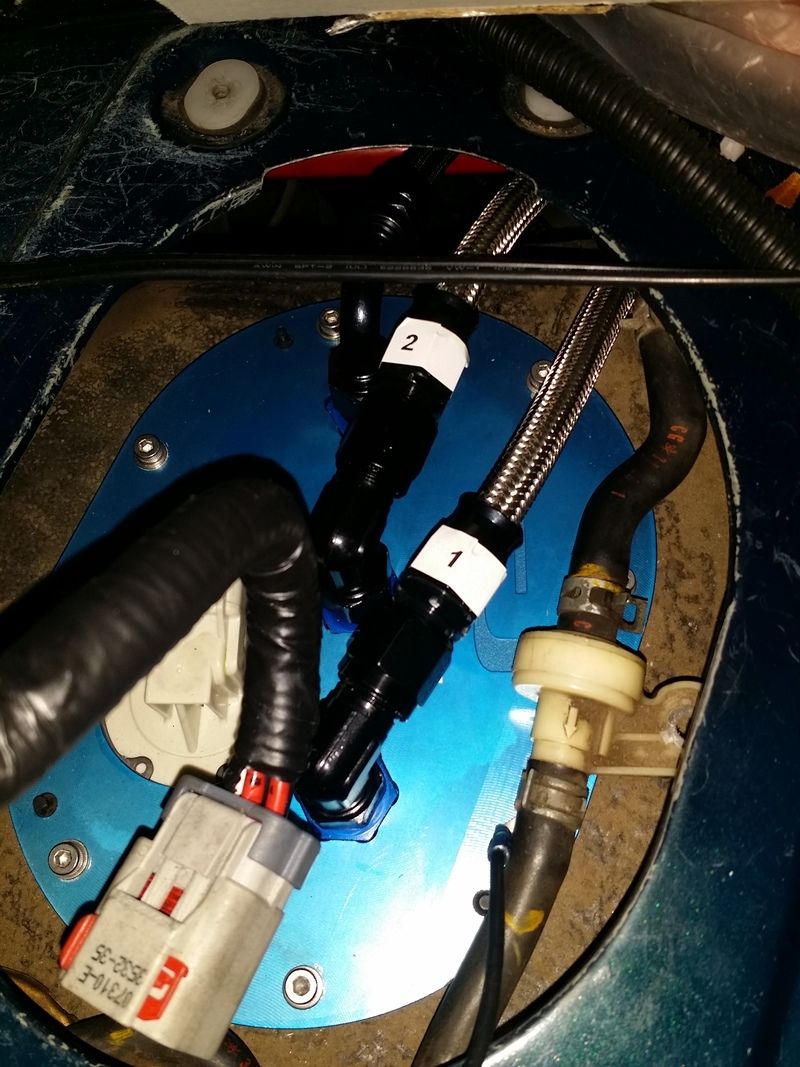

Thanks! I like it too. He brought the IC over today with the end tanks tacked up. We're going to just put the inlet and outlet at the bottom plate on both sides, and then just angle them where they need to go. He's also going to make the piping in sections so it'll look cool lol. We got the car running Saturday too. It's running on the Adaptronic and actually fires up easier than ever before, providing you blip the throttle once as you're cranking lol. My only concern is that it's running on the premise that the internal MAP sensor is selected when it's using the GM 3 bar. But honestly this doesn't really matter since I'm doing a new ECU anyway. I finished the battery hold-down, installed the rear bins and quarters, and tonight I built the Ohlins and pulled the STANCE coilovers. I'll be installing the Ohlins before I leave, but I'm trying to decide if I want to go ahead and do the Swift springs and install the brakes and everything else at the same time, or just wait for that stuff until I get back. I really don't want to pull these things twice in such a short time, but I would like to compare the two different springs. I hate to install such nice clean coilovers in such a nasty area, but I'm not sure I'll have time to get everything done before I leave. Here are some videos of it running.

https://www.youtube.com/watch?v=uo79vqgYro4https://www.youtube.com/watch?v=1SWvJ-bknKMKevin used the turbo as a hair dryer lol.

https://www.youtube.com/watch?v=80NZPlKZ2tsZico's guy came over and pulled the windshield Saturday too. He's supposed to come over and install the new one tomorrow. Once I decide what I'm going to do with the coilover project, I'll knock that out and put the fenders on, etc.

The rest of the AC vent got shipped today, so I'll fix that when it gets here and install the dash. I'd like to install it while the windshield is out lol, but I don't think that's gonna happen. I'm also going to see if I can find an iPad Mini 2 and start mocking that up in the dash while it's out.

Oh, and the slow cranking issue wasn't evident the first few times we started the car, but it showed itself a couple times later. So I'm not sure what that is but at least it starts correctly most of the time.

We also burped the coolant system, and it erupted like a volcano out of the Lisle funnel at one point lol. Turns out hot coolant really cleans an engine bay pretty well lol.