Saul_Good wrote:Can I watch? I like to learn things.

A little late now, but yes! lol

millertime wrote:You will have to make your own kiln or forge to get temps that high and keep them even. Lots of interesting info on knife-making forums.

Well, that's not gonna happen lol.

FDEEZ wrote:Basically the harder you make the steel, the less the material should come off as you try filing. Therefore, I would repeat the hardening process until little to no material is removed when you file.

Since this is a diy tempering process, I wouldn't expect you to be producing a part expected to withstand extreme tolerances (e.g. 20,000lb load). But it should be sufficient for your application.

Since you found a bolt that works...have you considered converting that bolt to a stud? IMHO, that may be the easiest option....besides just keeping that bolt in place.

Gotcha. I think I'll just keep trying to get some 60mm studs.

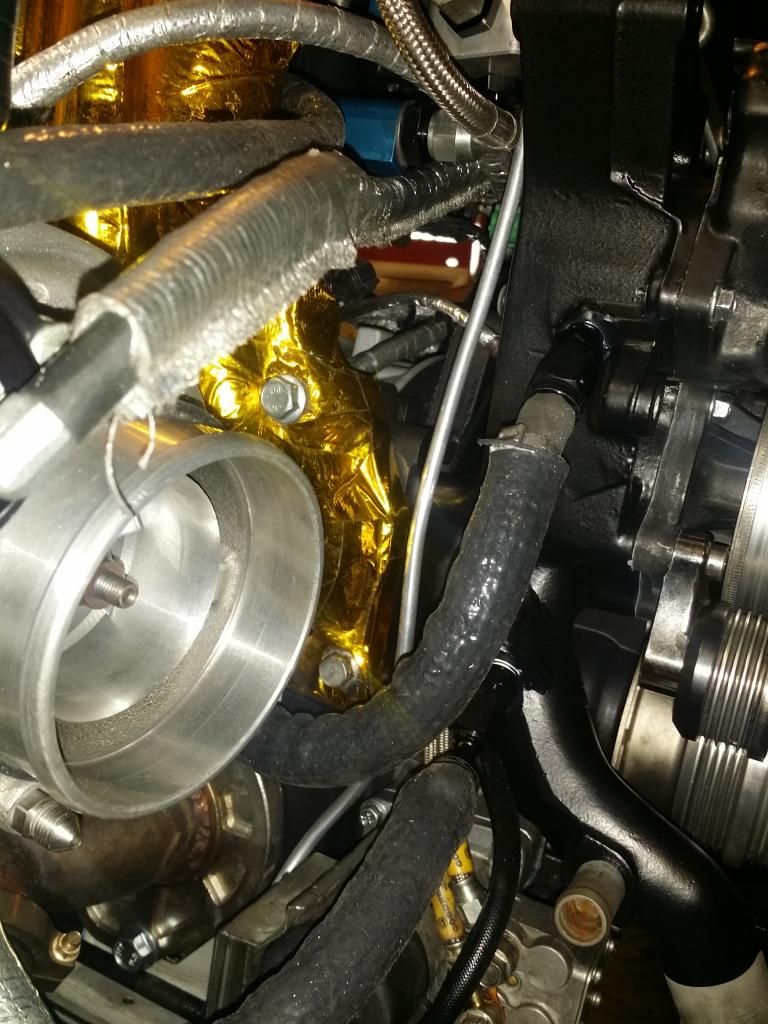

Luis came over earlier and helped me mount the turbo to the engine. I think I'm gonna try to install the engine with the turbo mounted this time. It was way easy to install it by myself the other night with no turbo, and I figure if I have someone on each side of the car watching and guiding the engine in, it should be fine. Plus it's easier than installing the turbo after.

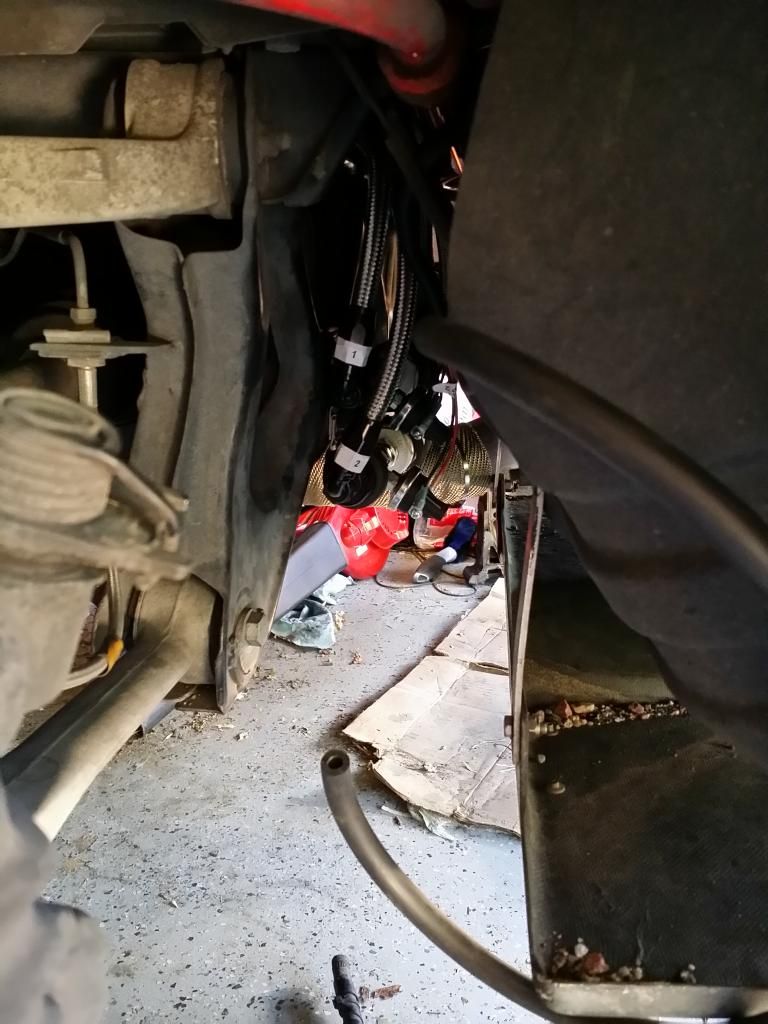

Here are some pics of the parts that came in today...

I was going to take a pic of them installed, but I forgot. I'll do that tomorrow. I still need to make the fuel lines and run the wires to the sensors anyway.

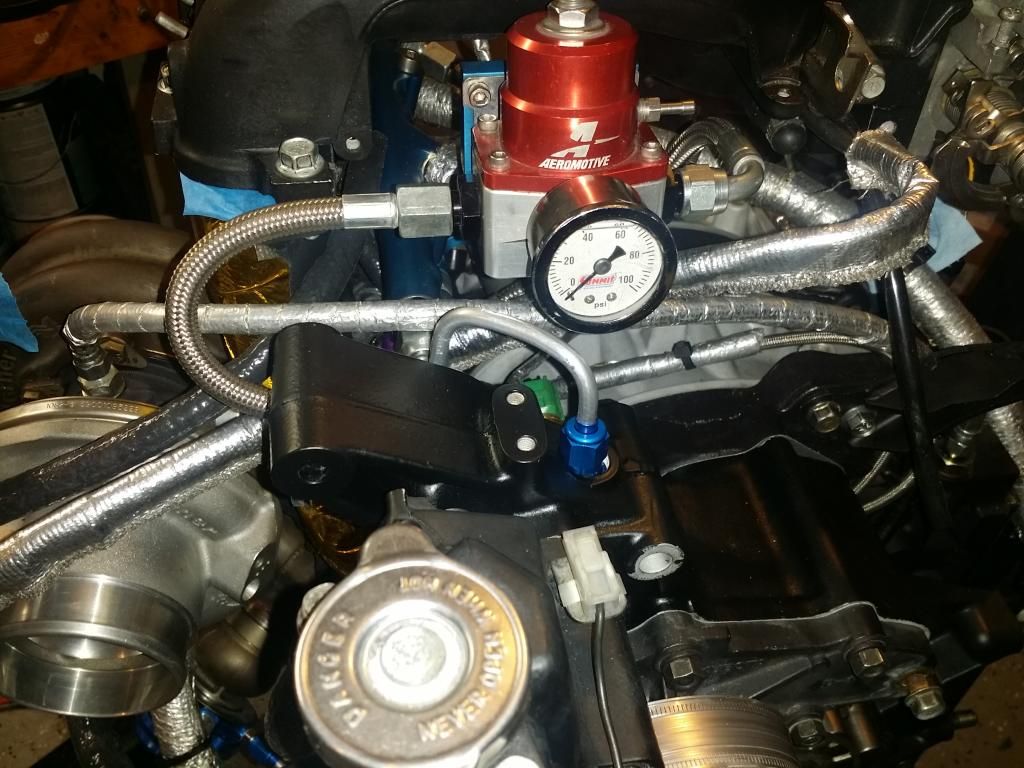

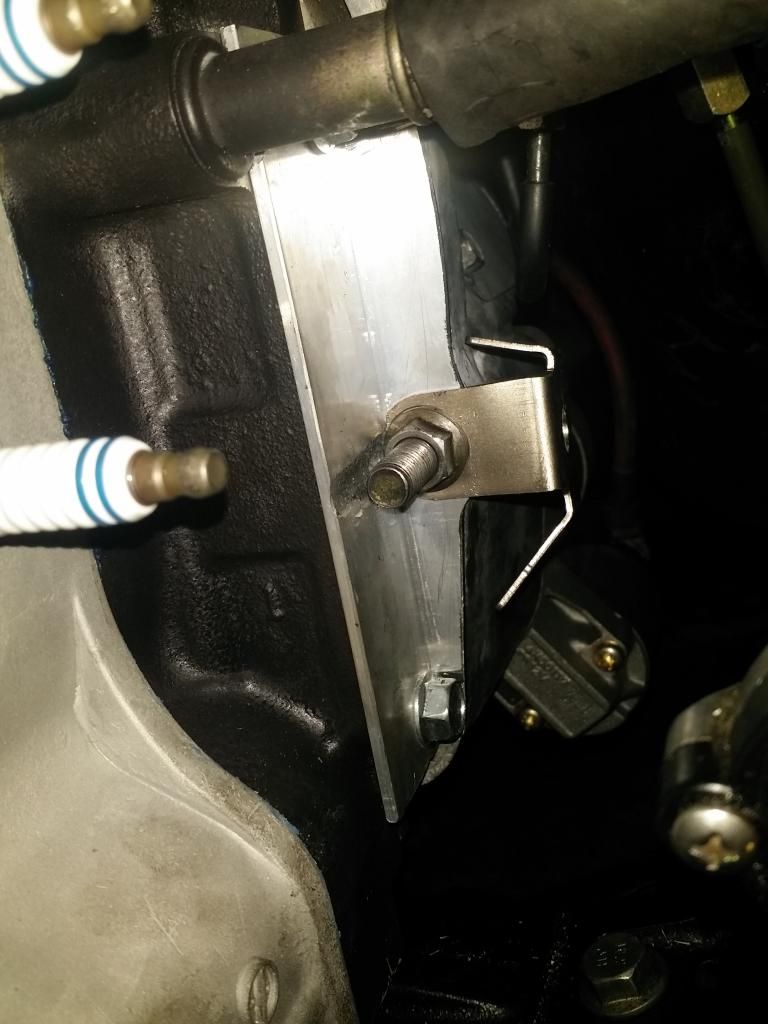

Here is the engine as it sits right now.

I made the coolant lines for the wastegates, and they came out pretty nice, and now that I see them installed I just want to get fittings for the rear iron and water pump housing so I can use them now lol.